Had an urge to buy some big boy toys so I bought 2 tools I've been considering for a while. Damn you tube video's!

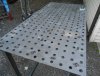

Mag Drill (Steel Dragon brand) and The Evolution brand Cold cut carbide metal chop saw. After looking at numerous reviews and weighing price vs features for far too long , I've settled on these two. Prices on these kind of tools can go WAY out beyond my budget into the thousands each, these ones are moderately priced.

, I've settled on these two. Prices on these kind of tools can go WAY out beyond my budget into the thousands each, these ones are moderately priced.

Got the chop saw for $384.00 w/free shipping and the mag drill that includes 6 annular cutters for $429.99 w/free shipping. One thing that got me to buy now is before all this "Fair tax" BS kicks in!! (some states already have it) Soon, everything you buy no matter what state the seller is in, you'll pay sales TAX! I'd hate to pay taxes on these kind of tools! Our government is so out of control... Ok, I'll save that for the political forum.

Anyone else here own these fun toys? (same or different brand)

Mag Drill (Steel Dragon brand) and The Evolution brand Cold cut carbide metal chop saw. After looking at numerous reviews and weighing price vs features for far too long

, I've settled on these two. Prices on these kind of tools can go WAY out beyond my budget into the thousands each, these ones are moderately priced.

, I've settled on these two. Prices on these kind of tools can go WAY out beyond my budget into the thousands each, these ones are moderately priced.Got the chop saw for $384.00 w/free shipping and the mag drill that includes 6 annular cutters for $429.99 w/free shipping. One thing that got me to buy now is before all this "Fair tax" BS kicks in!! (some states already have it) Soon, everything you buy no matter what state the seller is in, you'll pay sales TAX! I'd hate to pay taxes on these kind of tools! Our government is so out of control... Ok, I'll save that for the political forum.

Anyone else here own these fun toys? (same or different brand)

My chop saw is a off brand I bought from a traveling tool truck, not a high dollar unit ,but works for me.

My chop saw is a off brand I bought from a traveling tool truck, not a high dollar unit ,but works for me.

Not a big deal, just mentioning.

Not a big deal, just mentioning.

I will say one thing, IT'S HEAVY! 61 pounds! I'm going to make a cart or something, not going to be carrying this around much.

I will say one thing, IT'S HEAVY! 61 pounds! I'm going to make a cart or something, not going to be carrying this around much.