Thought I'd do this post as a "build in progress" instead of waiting until it's all done like I usually do. (no rush on this one, going for quality over speed but want it done before the warm weather as I have to get back to working on my cars!)

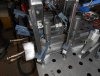

The past 2 days I've been preparing material & making parts for the new 2 x 72 belt grinder. The Evolution cold cut chop saw earned it's keep today.

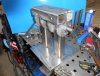

$50 bucks in metal so far with a few more things to get. Will be very strong/heavy since it's made from 2" x 1/4" square tube and 3/8" steel plate. It's time consuming working with thick metal like this but all part of the fun I guess.

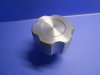

$50 bucks in metal so far with a few more things to get. Will be very strong/heavy since it's made from 2" x 1/4" square tube and 3/8" steel plate. It's time consuming working with thick metal like this but all part of the fun I guess.I bought the plans for this to make things go smoother and hopefully avoid any trial & errors. I will be sticking mostly to the original plan but I'm opting to make my own wheels since I already have the 2 & 3 inch round aluminum and all bearings in stock. (just need to buy a 7 inch slab of 6061 aluminum round stock for the drive wheel)

Motor will be a new Iron Horse 2hp AC 3 phase (already on it's way) and a VFD will be added to run it on my household 1 phase current. The VFD will allow forward/backward and speed control. The 2hp motor will make it run strong like bull! lol It should be a metal muncher!!!

It better be for what this thing is costing me!

It better be for what this thing is costing me!

I will also be fabricating a heavy duty roll-able metal cart to mount this on. I prefer to do most if not all grinding outside AWAY from my antique Chevy's!

If you would like to watch the video's on this grinder from the guy that designed it, here is a link to his "playlist" of all the video's. Many vid's to watch!

https://www.youtube.com/playlist?list=PL9skevFWrWc5Px-9pLq0vxaun8IyQojd2

Well, back to the metal supplier tomorrow.

(don't mind me, the coffee is kicking in)

(don't mind me, the coffee is kicking in)

(P.S. I like that young part!)

(P.S. I like that young part!)

I'll be making a roll-able cart for it so not a problem. I don't plan on carrying it anywhere.

I'll be making a roll-able cart for it so not a problem. I don't plan on carrying it anywhere.

First I have to get a more aggressive blade or I'll be here a week cutting it! Then remove the front fence and clamp some L brackets to secure it down. Then start cutting! I might have to rotate it a few times but it should cut thru.

First I have to get a more aggressive blade or I'll be here a week cutting it! Then remove the front fence and clamp some L brackets to secure it down. Then start cutting! I might have to rotate it a few times but it should cut thru.