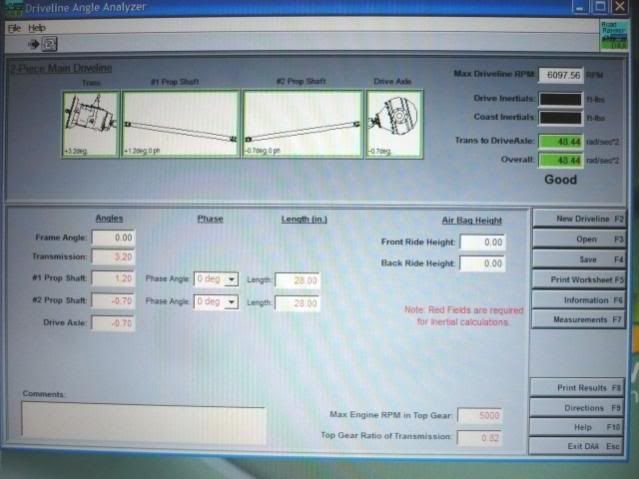

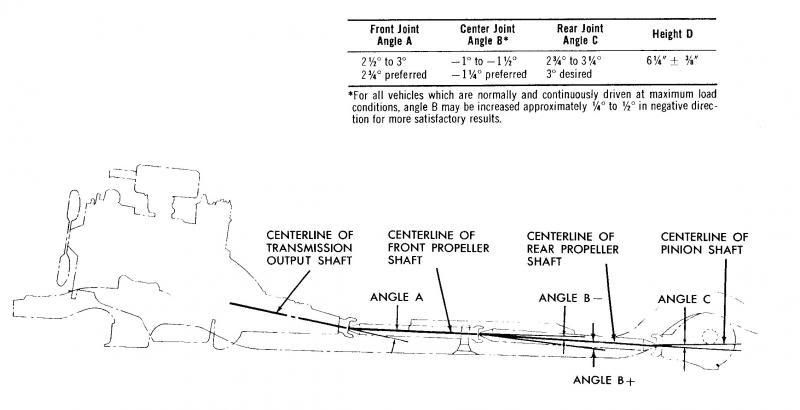

I always had a slight to sever vibration in the 62 since I installed the 700R4 (It's longer). It got the recommended angles out of whack. Before Winter closed in I talked to Suburban Driveline here in Chicago about multi shaft driveshafts in general. Seems the solution to my vibration was solved by the picture below. Align the first shaft with the transmission and deal with the other as if it was a single. Run the rear end angle the same as the transmission, 2 degrees down if you are using rubber bushings in the arms. I run a solid top and trac bar and poly in the lowers. Just a FYI on a slow, cold Chicago day.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new angle.

- Thread starter models916

- Start date

Thanks Models...... Exactly what I needed to know about my 700R4 installation........ great info !!!

Dave

Dave

Kdurgin

Well Known Member

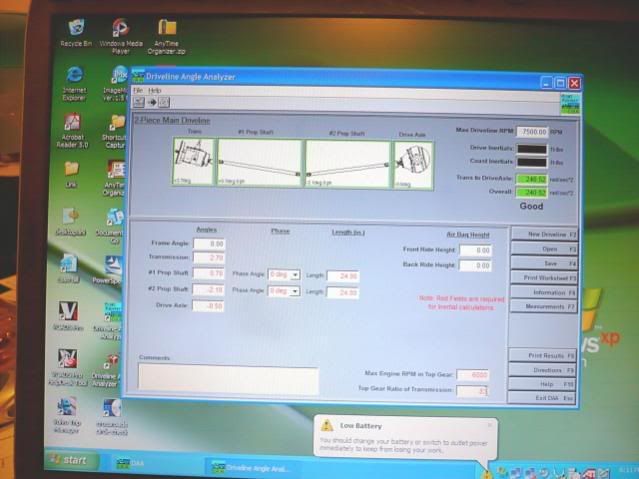

The problem you are going to have by trying to get your front shaft at the same angle as your engine is this: Your engine is probably somewhere around 3 degrees down to the rear. In order for you to run your front shaft at that same angle (3 degrees down to the rear) is you won't be able to lower your center bearing that far. I have my engine down around 3 degrees and my front shaft is down at the rear less than 1-1/2 degrees and I had to cut out the floor of my x-frame tunnel and lower the center bearing mount at least 3/4" You will have to go about double that and then the shaft may rub at the entrance or exit hole of the tunnel. Another thing, you may end up with a very severe angle between the 2 shaft sections unless you run a very high ride height. The info they gave you MAY be 100% correct, however you may have one hell of a time getting there. Driveshaft u-joint phasing comes heavy into play as well. My after market 3" Inland Empire shaft has different phasing than a stock shaft. I messed around with all this awhile back due to my Tremec TKO installation which was longer as well. IF you already have done this angle correction, I would like to see where your center bearing ended up for height. It was quite a PITA. Good luck.

It's a done deal..

I use the solid aluminum center bearing, and Late Great Chevy trans crossmember for the 700R4. Takes about a quarter inch of shims to 0 out the tailshaft of the trans with the first drivesaft. Adjustable rear upper solid banana bar to align the pinion. I went down my frontage road last week before the cold. Took it up past 90 mph/4:11 gears and all was smooth. My rear drive shaft is telescopic and I can change the phase if I need to. Now both U-joints are alighed.

I use the solid aluminum center bearing, and Late Great Chevy trans crossmember for the 700R4. Takes about a quarter inch of shims to 0 out the tailshaft of the trans with the first drivesaft. Adjustable rear upper solid banana bar to align the pinion. I went down my frontage road last week before the cold. Took it up past 90 mph/4:11 gears and all was smooth. My rear drive shaft is telescopic and I can change the phase if I need to. Now both U-joints are alighed.

sam 15

Active Member

Here's an article from Rod & Custom that might be helpful. It continues on page 2 and there is a link to Denny's Driveshafts

http://www.rodandcustommagazine.com/techarticles/0608rc_driveshaft_tech/driveshaft_support.html

Here's two w/pics

http://www.streetrodderweb.com/tech/0203sr_drive_shaft_angles/index.html

http://www.streetrodderweb.com/tech/0707sr_driveshafts/index.html

Here's another link that might be helpful

http://www.classicchevy5speed.com/Inland-Empire-Driveline.aspx

http://www.rodandcustommagazine.com/techarticles/0608rc_driveshaft_tech/driveshaft_support.html

Here's two w/pics

http://www.streetrodderweb.com/tech/0203sr_drive_shaft_angles/index.html

http://www.streetrodderweb.com/tech/0707sr_driveshafts/index.html

Here's another link that might be helpful

http://www.classicchevy5speed.com/Inland-Empire-Driveline.aspx

Kdurgin

Well Known Member

I understand and have been through all this when I set up my car. I am just questioning the ability to set your front shaft at the same angle as your motor and tranny without running into major clearance issues with the tunnel floor of the X-frame, especially with a longer tranny, your tailhousing is already low to start with. I know what I went through, and unless you cut out the floor of your tunnel or severely machine the bottom of the billet center mount, you can't lower it enough to maintain the 3 or so degree down angle on that front shaft. Also if the front shaft runs downhill at 3 degrees, and the pinion runs up at the same parrallel angle, you have a 6 degree split that needs to be made up between the 2 u-joint angles at the pinion joint and shaft to shaft joint as well.

It is aligned.

Took a pic today. Trans is very tight to the tunnel. Shaft has about .75" to the top. Still, nothing up front is moving, tight is tight not rubbing. And YES the pinion angle is the same as the front shaft. When the front shaft and the trans shaft are aligned, you are dealing with an extra long trans shaft with only ONE driveshart and set it up like that. My motor mounts may by lower than the original type 409 mounts. I use Energy Suspension poly for SBC.

Took a pic today. Trans is very tight to the tunnel. Shaft has about .75" to the top. Still, nothing up front is moving, tight is tight not rubbing. And YES the pinion angle is the same as the front shaft. When the front shaft and the trans shaft are aligned, you are dealing with an extra long trans shaft with only ONE driveshart and set it up like that. My motor mounts may by lower than the original type 409 mounts. I use Energy Suspension poly for SBC.

Attachments

I just used this information to set my driveline angles today. Seemed to eliminate my vibration on acceleration. Now I'll have to wait and see how it is on the highway. Thanks Models.I always had a slight to sever vibration in the 62 since I installed the 700R4 (It's longer). It got the recommended angles out of whack. Before Winter closed in I talked to Suburban Driveline here in Chicago about multi shaft driveshafts in general. Seems the solution to my vibration was solved by the picture below. Align the first shaft with the transmission and deal with the other as if it was a single. Run the rear end angle the same as the transmission, 2 degrees down if you are using rubber bushings in the arms. I run a solid top and trac bar and poly in the lowers. Just a FYI on a slow, cold Chicago day.