You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Poor boys 409 project

- Thread starter benchseat4speed

- Start date

As always, thanks to all you for the kind words. Means more than ya know. Especially compared to other forums (the hamb and coloradok5, cough cough) where no one gives two shits if you're alive or not. You're the only 'cyber group' that know about this accident. I don't have facebook or twitter or any of that crap.

Next update will be the engine.

Next update will be the engine.

Ok, I confess. I have a JD rider and my Knuck parked by the Crusher..... My last Mopar resides at the bottom of my sand pit.

My last Mopar resides at the bottom of my sand pit.

My last Mopar resides at the bottom of my sand pit.

My last Mopar resides at the bottom of my sand pit.

Last edited:

Glad your doing well Kevin!!As always, thanks to all you for the kind words. Means more than ya know. Especially compared to other forums (the hamb and coloradok5, cough cough) where no one gives two shits if you're alive or not. You're the only 'cyber group' that know about this accident. I don't have facebook or twitter or any of that crap.

Next update will be the engine.

I'm really envious of that interior!! I love it!!

I'm really envious of that interior!! I love it!!

Rick

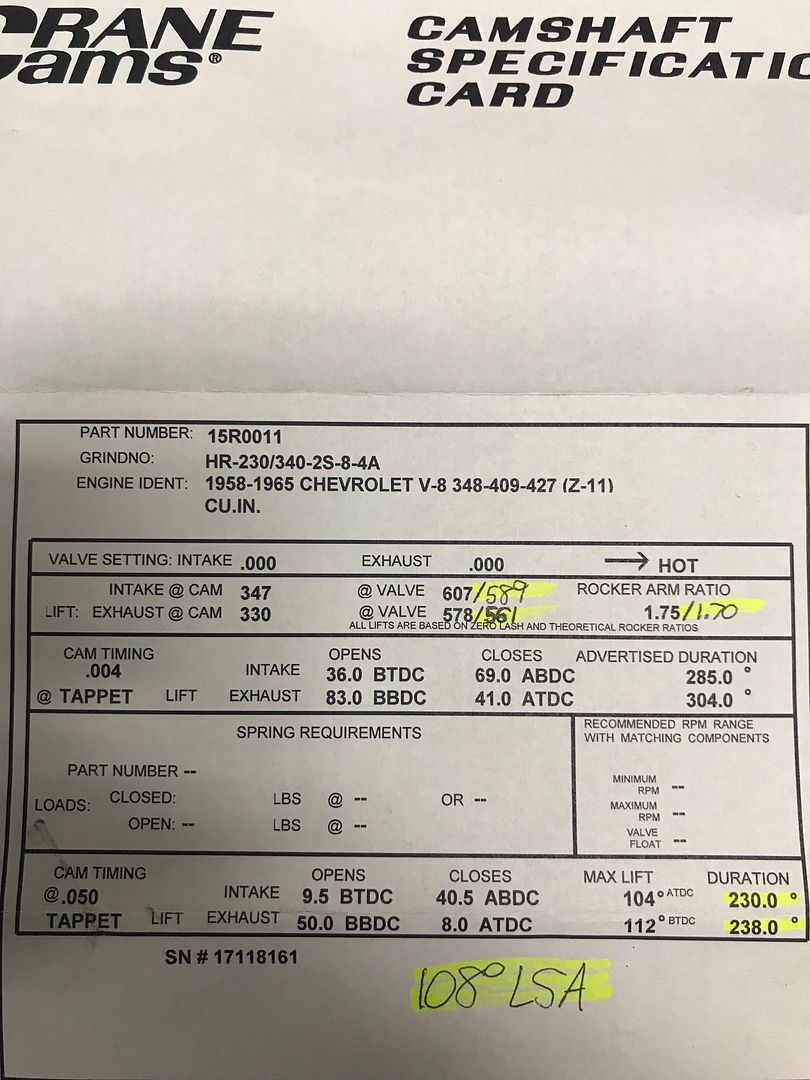

Here it is almost 5 years after I bought this engine, close to four years after I bought the car. I finally married the two about a month ago, and I just fired the engine for the first time last weekend.

Been watching my pennies the whole time. Even doing this thing on the ‘cheap’, it still cost me...

$10,518.84 for the engine, carb to pan and,

$27,684.08 for the whole car (engine cost included) bumper to bumper, turn key. I included everything though. Every nut and bolt, every can of paint, lenses, keys, tires, everything. I also included initial purchase prices. $1,500 for the car, $1,200 for the engine.

This is gonna take a few posts to cover. My build plans for this engine changed 3-4 times in 3-4 years as my budget increased with pay raises at work. I ran into several issues building it, and several events in life kept stalling it and dragging it out. This car/engine have cost me thousands of hours, dollars, and I cussed this thing hundreds of times. This SOB finally runs though and I love it. Put 150 miles on it so far.

To recap, here’s what I started with. Bone stock, QC code 422 block, 817 heads, wrong intake and exhaust manifolds. Initial plan was to ring and bearing it, reseal it, and drop it in my more door Bel Air. That dream was shattered when I pulled the intake off and found a huge mouse nest in the lifter valley. (Whoever swapped the engine in left the hole for the draft tube in the back of the intake wide open) This was after I ran it in the truck, so the pickup screen was completely clogged with that s—t. It was wrapped around the pushrods, wrapped around the camshaft, it was bad. Pulled the heads, pistons were junk. Someone detonated the hell out of this thing. Pulled the pan and a few main/rod caps, this thing had the worst bearings I’ve ever seen. The crank journals were hosed. So that burst the bubble on plan one....

Been watching my pennies the whole time. Even doing this thing on the ‘cheap’, it still cost me...

$10,518.84 for the engine, carb to pan and,

$27,684.08 for the whole car (engine cost included) bumper to bumper, turn key. I included everything though. Every nut and bolt, every can of paint, lenses, keys, tires, everything. I also included initial purchase prices. $1,500 for the car, $1,200 for the engine.

This is gonna take a few posts to cover. My build plans for this engine changed 3-4 times in 3-4 years as my budget increased with pay raises at work. I ran into several issues building it, and several events in life kept stalling it and dragging it out. This car/engine have cost me thousands of hours, dollars, and I cussed this thing hundreds of times. This SOB finally runs though and I love it. Put 150 miles on it so far.

To recap, here’s what I started with. Bone stock, QC code 422 block, 817 heads, wrong intake and exhaust manifolds. Initial plan was to ring and bearing it, reseal it, and drop it in my more door Bel Air. That dream was shattered when I pulled the intake off and found a huge mouse nest in the lifter valley. (Whoever swapped the engine in left the hole for the draft tube in the back of the intake wide open) This was after I ran it in the truck, so the pickup screen was completely clogged with that s—t. It was wrapped around the pushrods, wrapped around the camshaft, it was bad. Pulled the heads, pistons were junk. Someone detonated the hell out of this thing. Pulled the pan and a few main/rod caps, this thing had the worst bearings I’ve ever seen. The crank journals were hosed. So that burst the bubble on plan one....

Time flys when your having fun Kevin. (Money too). Now we need pictures of completed car and engine compartment. You still have your other cars???

Keep at Kevin,

Time is relative, it is more about the process.

Time is relative, it is more about the process.

So I started to formulate plan two in April/May of 2014. A lot happened between then and now, and the plan changed a few times. But the end result was this. Here’s what’s in the bottom end.

-Bore: 4.320”

-Stock Chevrolet 072 crank, cleaned up .010/.010

-Callies 6.385” rods, ARP wave loc bolts

-Ross “11:1” pistons, opted for the contour milling to make them as light as possible

-Total Seal gapless (bottom) rings

-Clevite bearings

-Melling M55 pump, stock pickup

-windage tray from show cars

-stock oil pan

My bastard Ross pistons. Ordered ‘standard’ 11:1’s with slightly deeper valve reliefs and here’s what I got. Tried to smooth out all the sharp edges on these domes. Better flame travel maybe? I dunno.

Some miscellaneous specs....

-pistons are .023”-.028” below the deck

-compression is 10.8:1 with a .020” steel shim (would’ve been 10.2:1 with a .040 composite)

-Ross pistons weigh 820-822 grams, no pins or locks

-Original QB rod and piston, pin, rings, bolts, and a bearing is 1903.30 grams

-Ross piston with Callies rod, pin, locks, rings, bolts, and bearing is 1918.90 grams

-Bore: 4.320”

-Stock Chevrolet 072 crank, cleaned up .010/.010

-Callies 6.385” rods, ARP wave loc bolts

-Ross “11:1” pistons, opted for the contour milling to make them as light as possible

-Total Seal gapless (bottom) rings

-Clevite bearings

-Melling M55 pump, stock pickup

-windage tray from show cars

-stock oil pan

My bastard Ross pistons. Ordered ‘standard’ 11:1’s with slightly deeper valve reliefs and here’s what I got. Tried to smooth out all the sharp edges on these domes. Better flame travel maybe? I dunno.

Some miscellaneous specs....

-pistons are .023”-.028” below the deck

-compression is 10.8:1 with a .020” steel shim (would’ve been 10.2:1 with a .040 composite)

-Ross pistons weigh 820-822 grams, no pins or locks

-Original QB rod and piston, pin, rings, bolts, and a bearing is 1903.30 grams

-Ross piston with Callies rod, pin, locks, rings, bolts, and bearing is 1918.90 grams

Last edited:

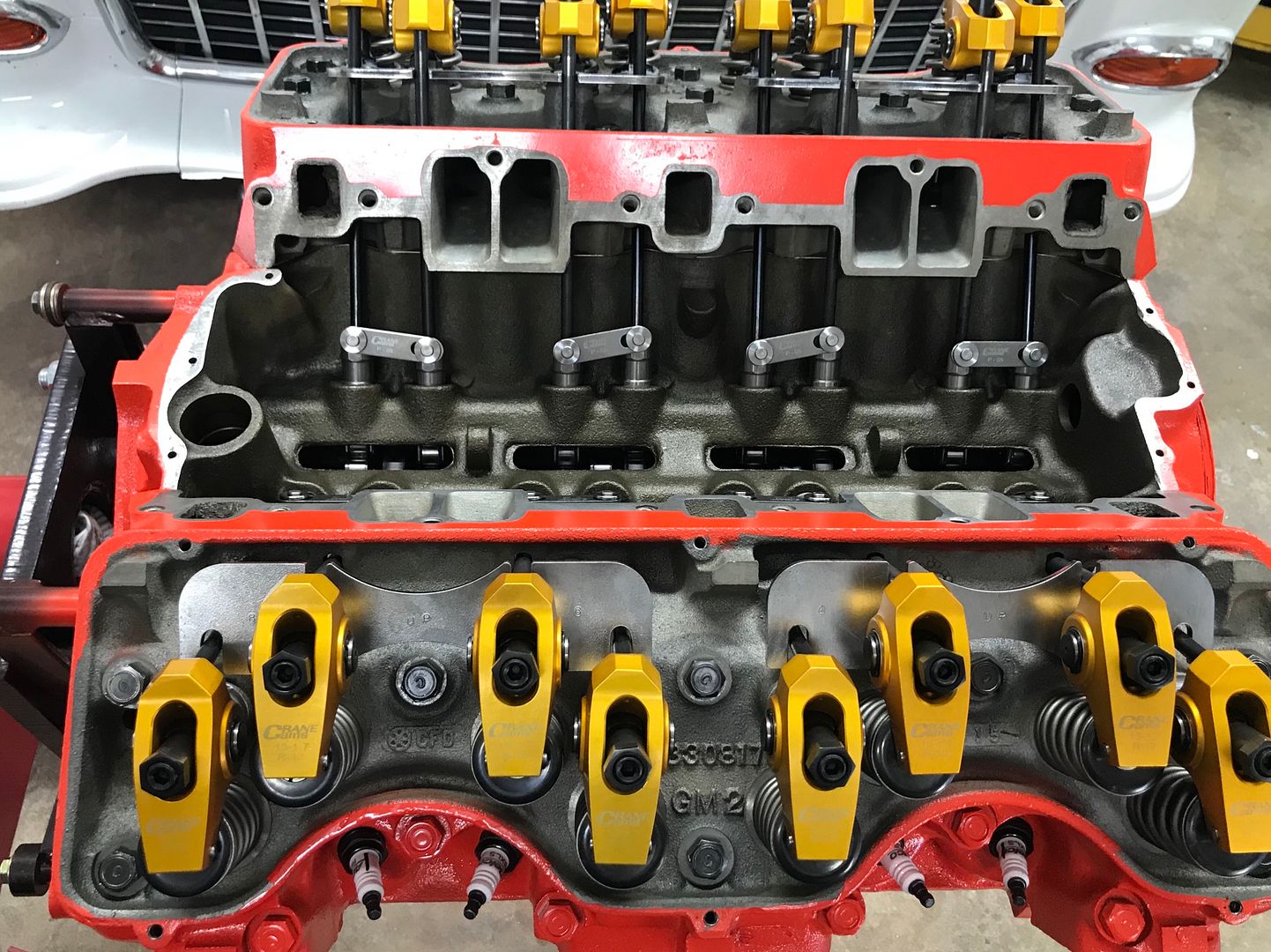

I was very impressed at how much power Yellow Wagon made with his 333’s, and wanted to see what I could do with some 817’s. I did quite a bit of reading, Steve Dulcich/engine masters were very helpful with basic head porting info. I did a lot of work under under the valves, exhaust side especially, rounded and smoothed out the ‘short side’ on the intakes, gasket matched the intake ports, and took a little off the pushrod pinch. I was afraid to hit water, so I didn’t go crazy. I never put these on a flow bench either, so I dunno if I did any good. Some, hopefully.

Some specs on the heads:

-intake runner volume after porting 197cc

-exhaust runner volume after porting 120cc on #1, 115cc on #3

-chamber volume is 9cc after .005” milled off

-machined .530” off the rocker stud bosses to accommodate 7/16” screw in studs, ARP-135-7121 on intakes, ARP-235-7204 on exhaust

-show cars .190” guide plates

-2.06/1.72 valves

Some specs on the heads:

-intake runner volume after porting 197cc

-exhaust runner volume after porting 120cc on #1, 115cc on #3

-chamber volume is 9cc after .005” milled off

-machined .530” off the rocker stud bosses to accommodate 7/16” screw in studs, ARP-135-7121 on intakes, ARP-235-7204 on exhaust

-show cars .190” guide plates

-2.06/1.72 valves

Last edited:

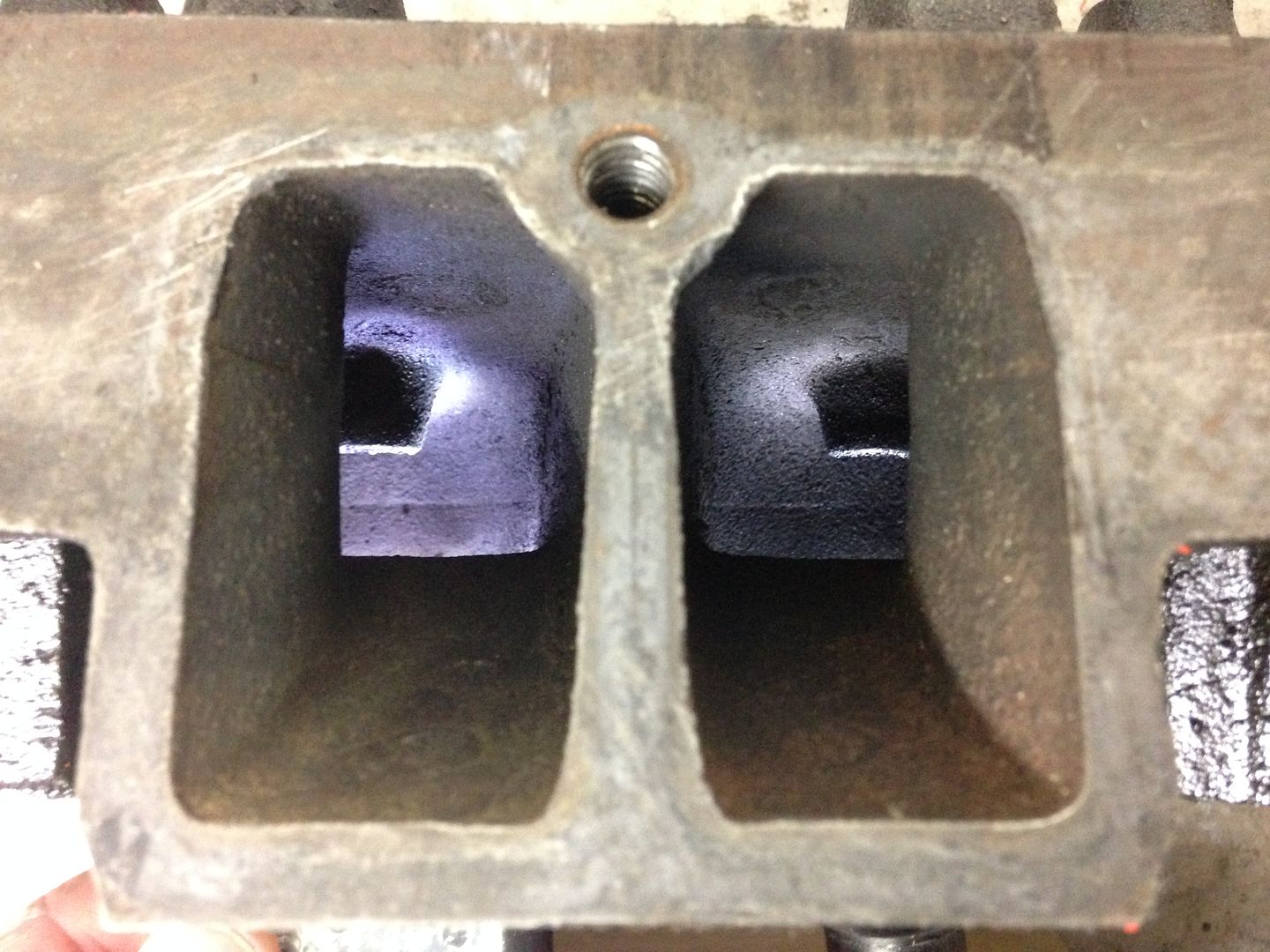

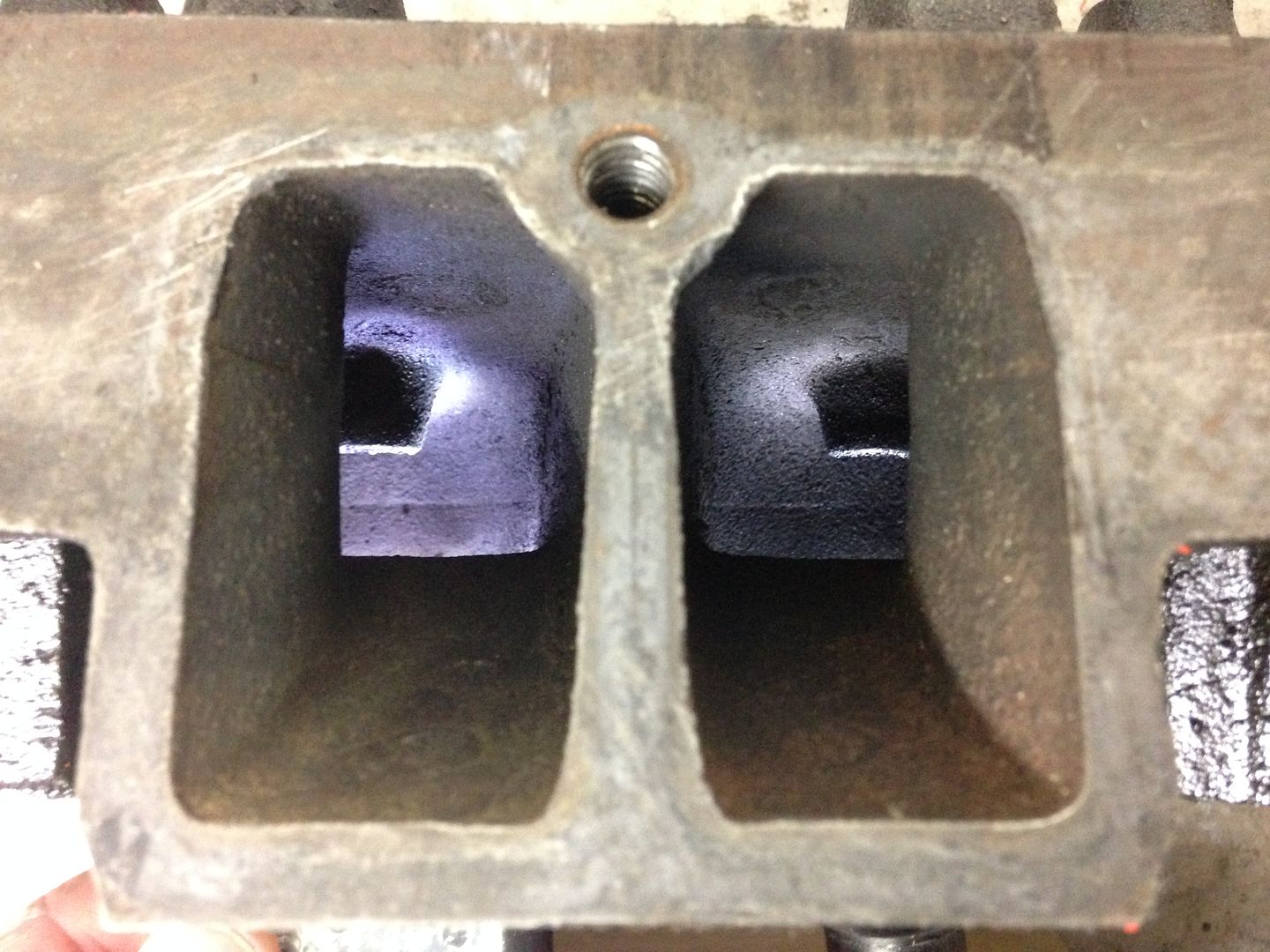

I originally planned to run a single four, but this old beater Offy showed up at a swap meet last year for 150 bucks. The plenum design looked very poor to me, as cast. Straight down, and a sharp 90* into the ports. I ported the hell out of it to try and pick up some flow. Ended up with a pretty straight shot into the ports.

Before

After

Before

After

Cut up the old draft tube and rigged a PCV. ‘60 348 distributer with Pertronix ignitor II.

Last edited:

I even, have a Therm-quad.

I even, have a Therm-quad.