Topstrap

Well Known Member

Now that I have my chassis about done and waiting on the engine from Bob I needed to get started on the body. Asked around to try and borrow a rotisserie from various buddies but all are either being used, loaned out or just can't remember where it is or who has it. So, I had some H-beams from a job I did and took them as partial payment. They were kinda heavy but didn't have anything in them so I figured I had a starting point. Not the easiest thing to work with since box tubing makes it so much easier but I have a welder, torch and a streak of stubborness that gets me in trouble sometimes.

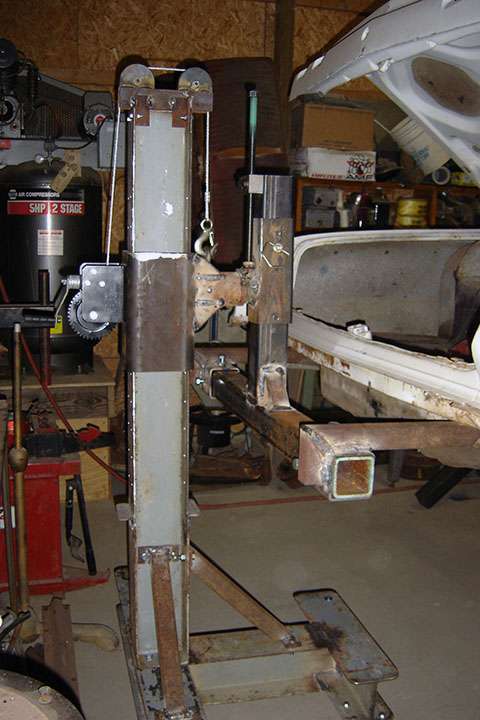

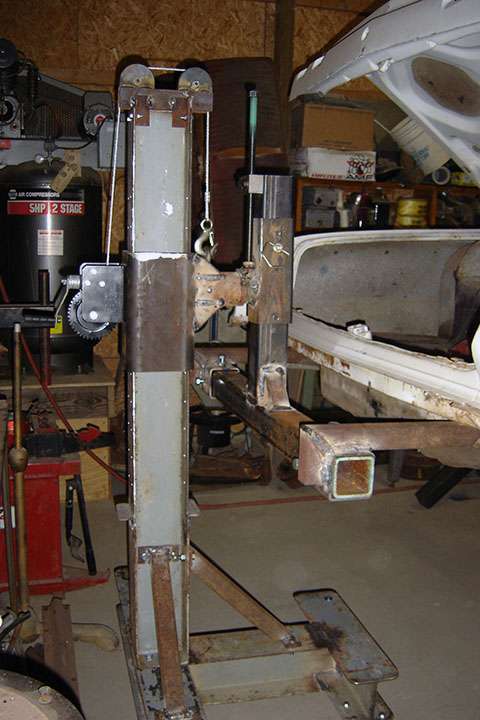

Didn't take any pictures during construction since I doubt anyone would try to make one like this anyway. It's heavy, maybe overkill and not properly engineered but I got it connected to the car today and believe it or not it works as far as the balancer and raising the body with the winch. Works unbelievably smooth and nearly effortlessly. Leaving for Street Rod Nationals in Louisville in the morning so it'll have to (hopefully) stay level till I get back and make the connector between the two assemblies then try to balance it out and rotate it.

I did do a bit of research on the net and looked at a lot of pictures before I started this and had an idea of what I hoped it would look like when done. I'm so sick of drilling holes, grinding steel and welding for a long time. Probably been better to buy one but I doubt it would have been this stable or strong and I do like making things, just don't have the skill to make it look factory built. Redneck all the way and bigger is usually better. I did make it so it'll all come apart and stack along the wall. Hope it holds up, I'm not building another one.

H-beams in the weeds.

Started cutting rough lengths out.

Yay, it stands by itself.

Paint? Don't need no stinking paint. Kinda like the rough, scruffy look.

Looking at the pictures maybe a coat of paint might hide the ugly welds.

For the balancer I initially tried welding 3 fine threaded 3/4" nuts together to have something with a lot of thread to help support the weight and still be able to spin the threaded rod into to set the balance point of the car.. FAIL Left the grade 8 threaded rod in to help align them and it warped so tight I ruined that rod and had to start over. Had a piece of 1 1/2" plate I torched out a section then proceeded to mill it flat and cut 3/4" fine threads thru it to thread the balancing rod into. Much better idea and works great.

The H-beam was 6" so I thought I'd get a piece of square tubing to slide down over it. All they had was 7" with a 1/2" thick wall so I thought that would fit. Forgot about the inside being curved so I had to trim 1/4" from all 4 sides of my H-beam then round off the edges to they'd let the square tubing slide over it with a nice fit.

Don't show them but have two 1/2" hardened steel rods that can be slipped into the H-beam and under the main slider for safety and support the weight when correct working height is set.

Will add to this when I get back and we finish up the connector and try to rotate it.

Now to get packed and head down tomorrow and get ready to spend Friday and Saturday searching out stuff for our 62 Impala. I can taste the ribs at Chili's already and looking forward to the Swap Meet area for any bargins and unexpected treasures we may need. Chris has a long list of things like interiors, wheels, rubber kits and paint. Hoping to see a lot of old Chevys and get some ideas on color schemes and how each owner details. Wish we could drive the 32 down but I'd have to pry Chris out with a spoon. He's 6'6", a big boy and that lil 32 with the chopped top and channeled body is pretty uncomfortable for him.

Dennis and Chris

Didn't take any pictures during construction since I doubt anyone would try to make one like this anyway. It's heavy, maybe overkill and not properly engineered but I got it connected to the car today and believe it or not it works as far as the balancer and raising the body with the winch. Works unbelievably smooth and nearly effortlessly. Leaving for Street Rod Nationals in Louisville in the morning so it'll have to (hopefully) stay level till I get back and make the connector between the two assemblies then try to balance it out and rotate it.

I did do a bit of research on the net and looked at a lot of pictures before I started this and had an idea of what I hoped it would look like when done. I'm so sick of drilling holes, grinding steel and welding for a long time. Probably been better to buy one but I doubt it would have been this stable or strong and I do like making things, just don't have the skill to make it look factory built. Redneck all the way and bigger is usually better. I did make it so it'll all come apart and stack along the wall. Hope it holds up, I'm not building another one.

H-beams in the weeds.

Started cutting rough lengths out.

Yay, it stands by itself.

Paint? Don't need no stinking paint. Kinda like the rough, scruffy look.

Looking at the pictures maybe a coat of paint might hide the ugly welds.

For the balancer I initially tried welding 3 fine threaded 3/4" nuts together to have something with a lot of thread to help support the weight and still be able to spin the threaded rod into to set the balance point of the car.. FAIL Left the grade 8 threaded rod in to help align them and it warped so tight I ruined that rod and had to start over. Had a piece of 1 1/2" plate I torched out a section then proceeded to mill it flat and cut 3/4" fine threads thru it to thread the balancing rod into. Much better idea and works great.

The H-beam was 6" so I thought I'd get a piece of square tubing to slide down over it. All they had was 7" with a 1/2" thick wall so I thought that would fit. Forgot about the inside being curved so I had to trim 1/4" from all 4 sides of my H-beam then round off the edges to they'd let the square tubing slide over it with a nice fit.

Don't show them but have two 1/2" hardened steel rods that can be slipped into the H-beam and under the main slider for safety and support the weight when correct working height is set.

Will add to this when I get back and we finish up the connector and try to rotate it.

Now to get packed and head down tomorrow and get ready to spend Friday and Saturday searching out stuff for our 62 Impala. I can taste the ribs at Chili's already and looking forward to the Swap Meet area for any bargins and unexpected treasures we may need. Chris has a long list of things like interiors, wheels, rubber kits and paint. Hoping to see a lot of old Chevys and get some ideas on color schemes and how each owner details. Wish we could drive the 32 down but I'd have to pry Chris out with a spoon. He's 6'6", a big boy and that lil 32 with the chopped top and channeled body is pretty uncomfortable for him.

Dennis and Chris