Any guesstimate on final weight for comparison?

Same question here, I want a light weight motor and your project has made me seriously consider a 409.

Any guesstimate on final weight for comparison?

bang

bang

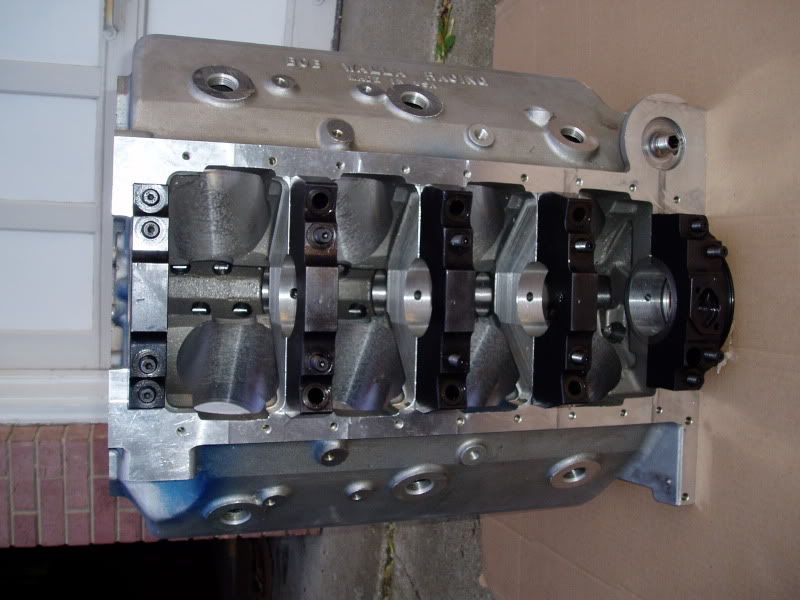

Hey Jim: How's the machining going?

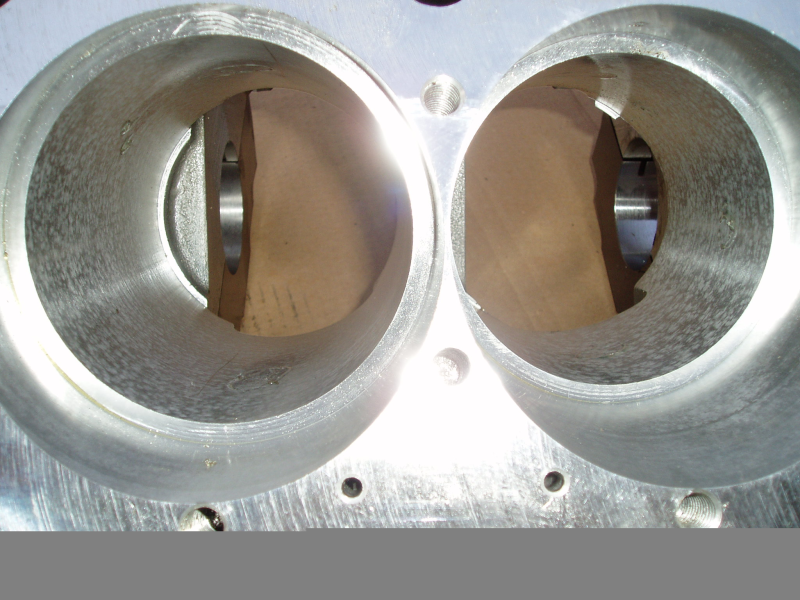

I'll need to get a one quart oil can from Phil to see if it slides in. Region Rat

Aubrey, You probably have a back like mine. You can only wrestle so many of those blocks around before you need the heating pad. Bob