Sera

Active Member

Sorry, not an Impala....

I bought this car back in 2011, having always hankered after a 2nd gen F-body. The intention was to keep it on the road and do little bits and pieces to it over the course of a few years and slowly get it upgraded into an everyday car.

That idea didn't last very long...

As soon as I dug into the car I discovered a lot of rust - perhaps unsurprising after finding out the car has been in the UK since 1982, with no rust protection whatsoever.

So I took it off the road and started what turned into 2 years of repairs.

When I bought the car, some bright spark had decided it would be a good idea to paint it like bumblebee... with a roller. Possibly the worst paint job I've seen. But the car was cheap.

It had a completely gutless 305 SBC fitted, which smoked a bit from the right bank. Other than that it drive OK, so I ran around in it for a couple of months.

After digging around in it for a while I started to realise just how badly bodged it had been. It had 11 months MOT on it when I bought it... possibly given by someone with a labrador and white stick...

It turned out to be rotten, really rotten. But I'd paid so little for it, and I had the time on my hands and a welder... to just patch it up.

I ended up stripping the whole shell back to bare metal and cutting out every piece of rot I could find. The only panel that I didn't end up having to repair or replace was the roof.

After that the underside of the car was treated with Jotamastic, and the rest of the bodywork with 2k epoxy primer.

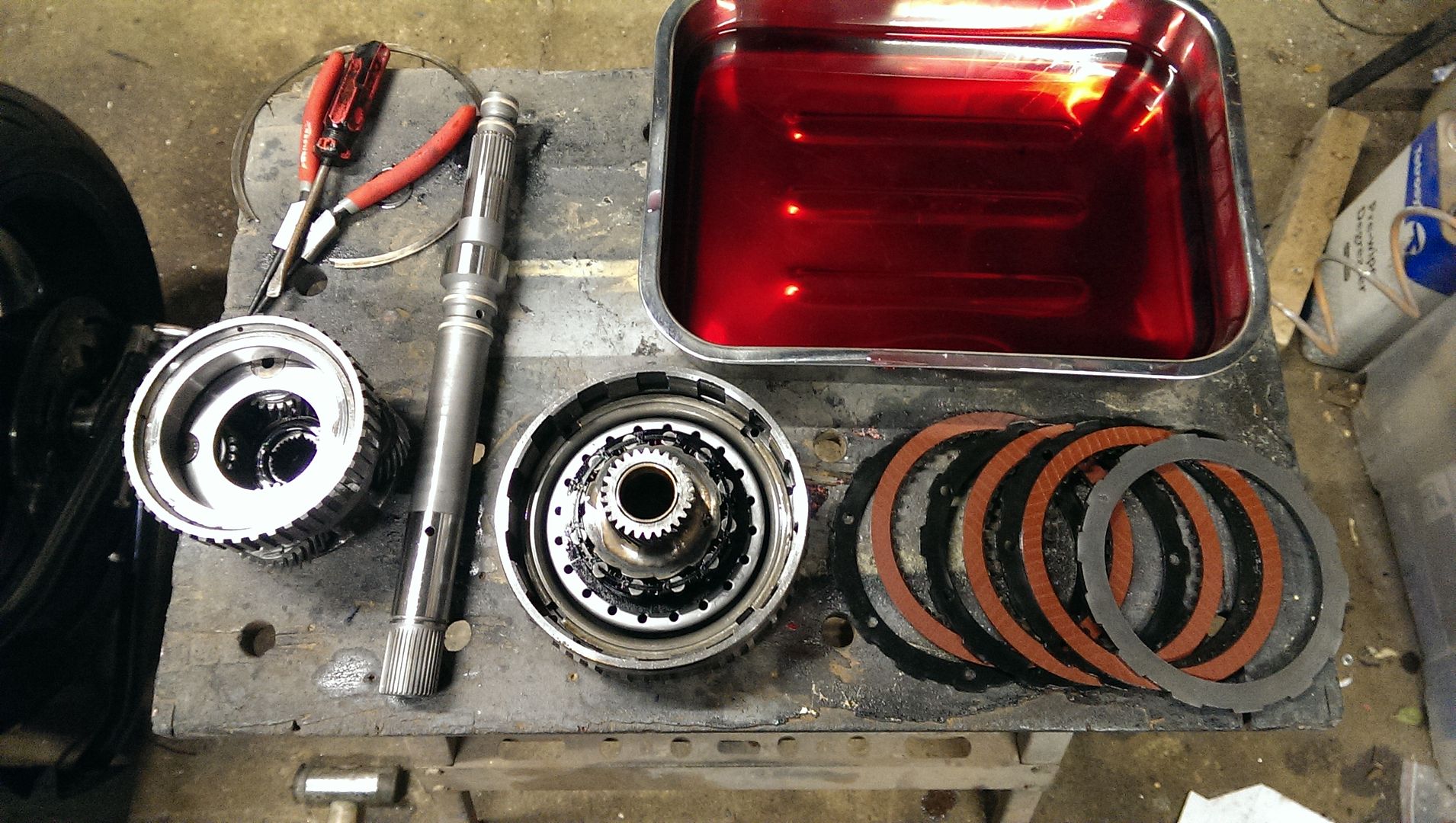

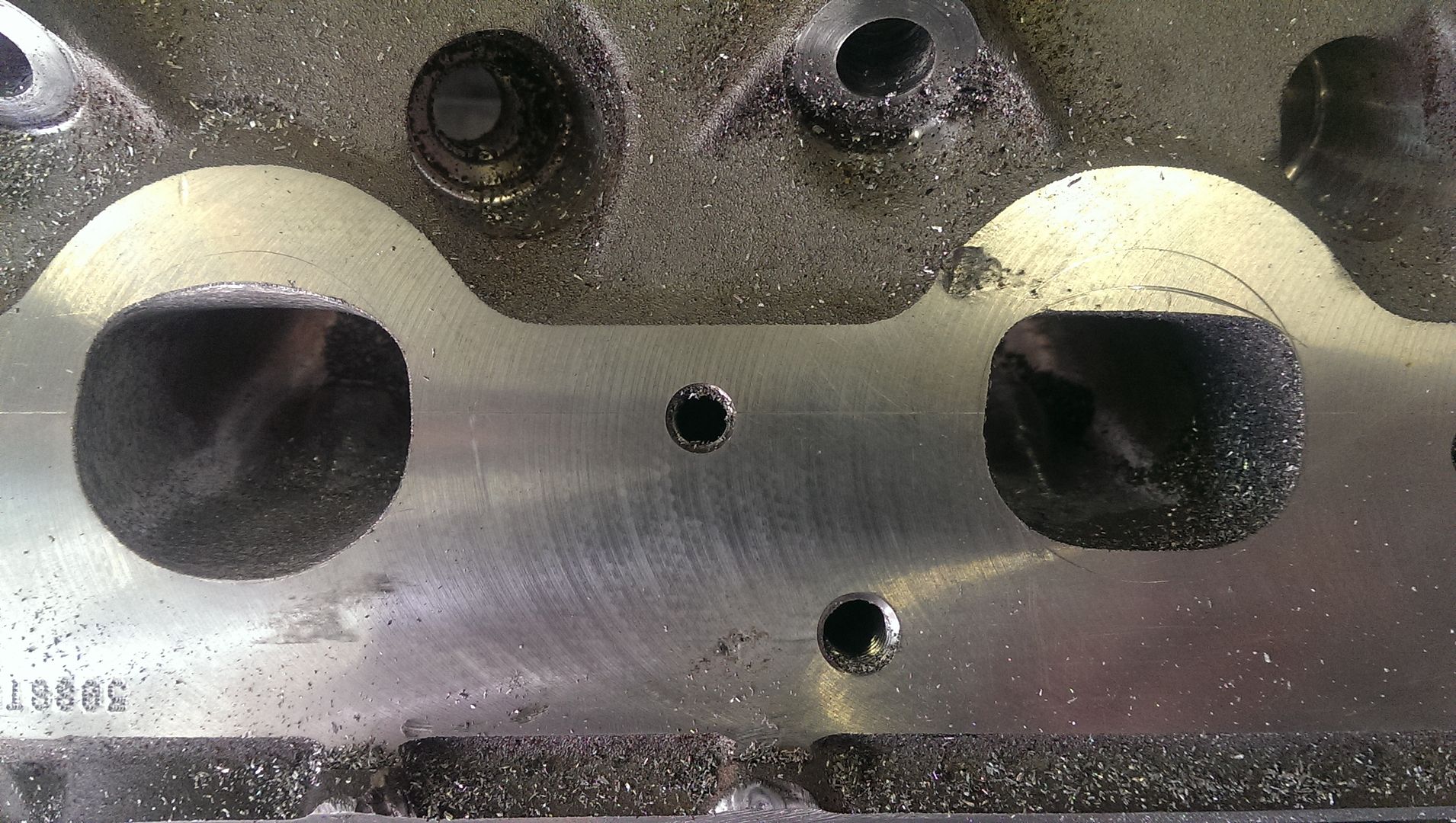

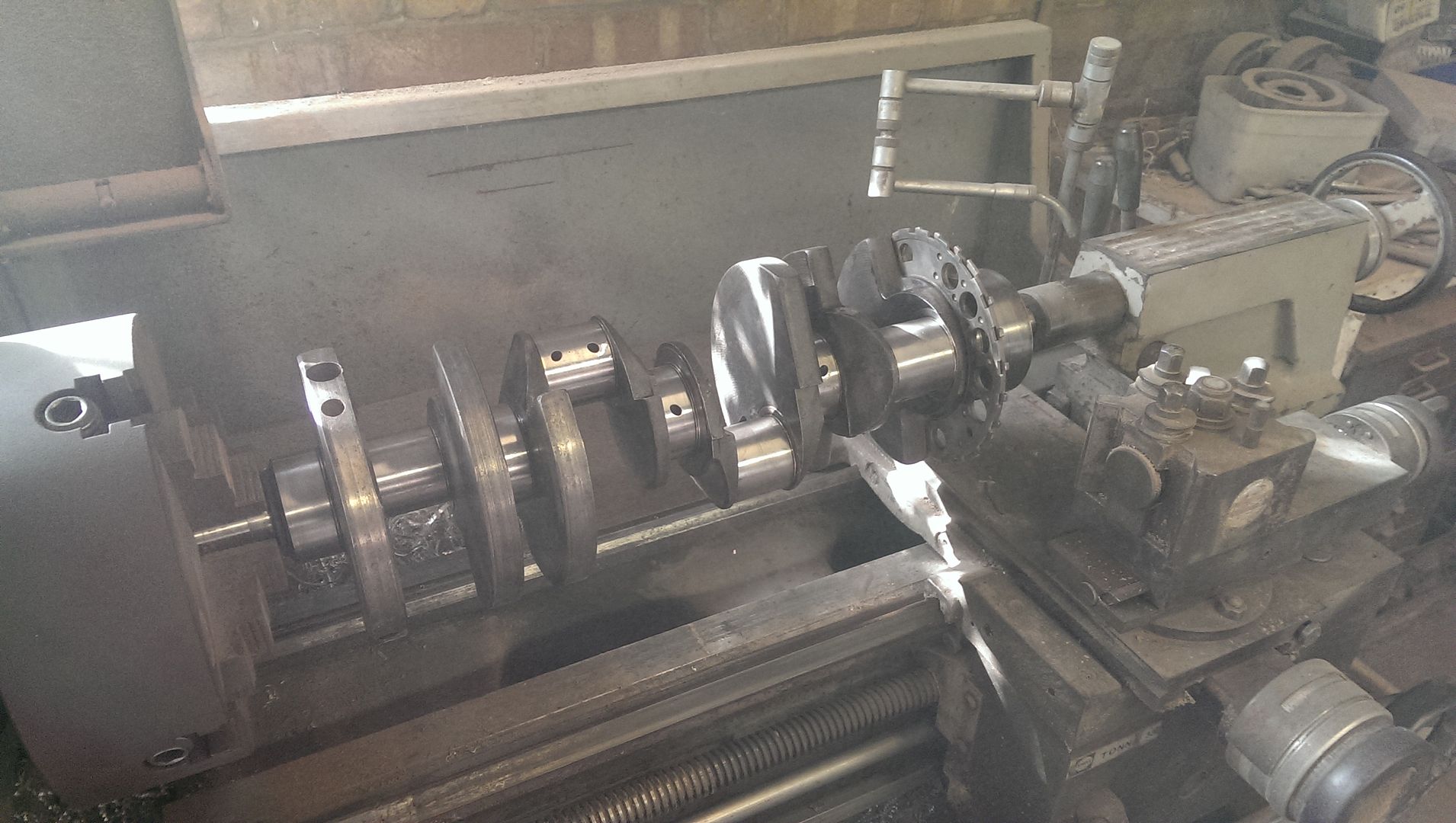

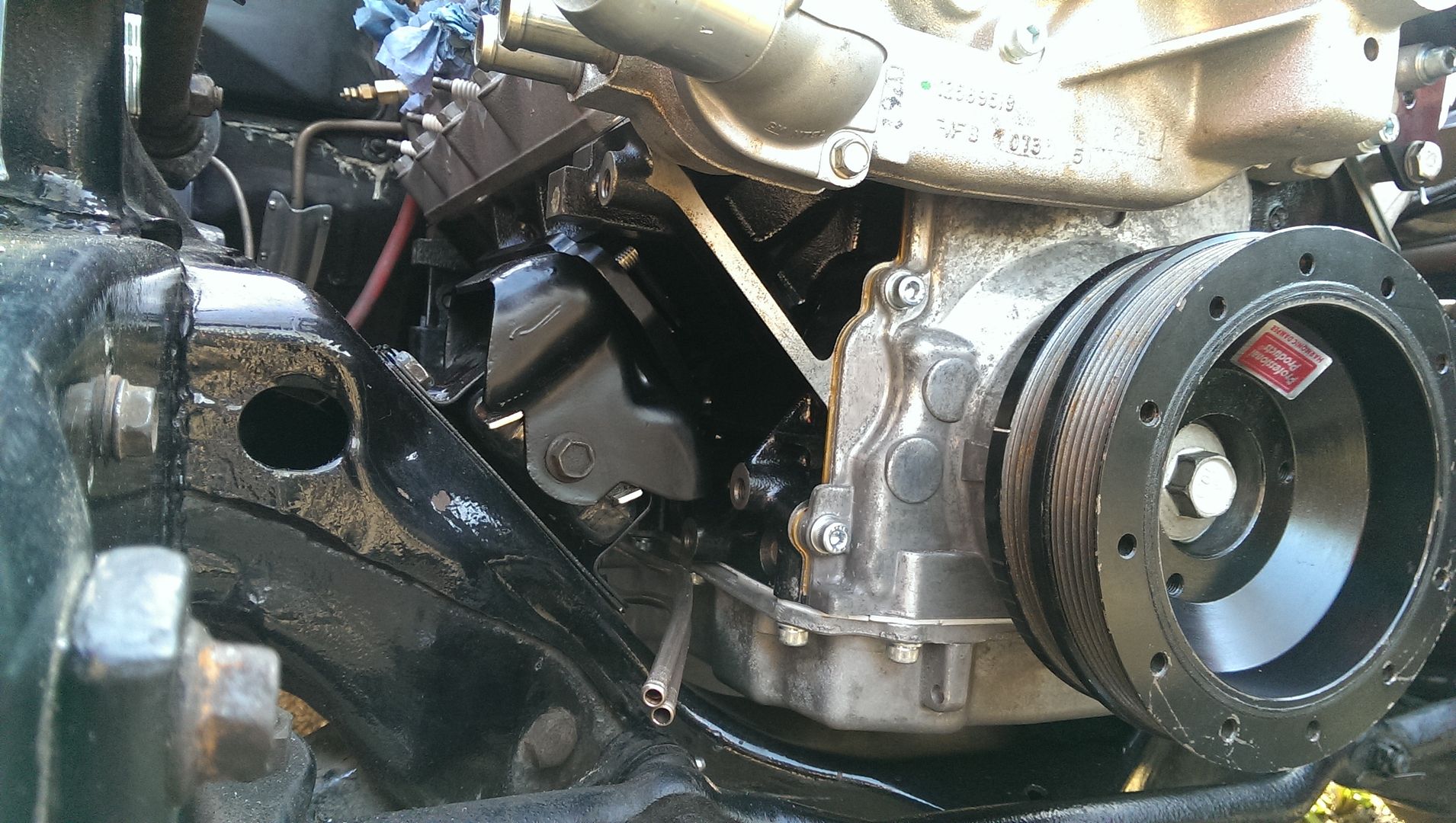

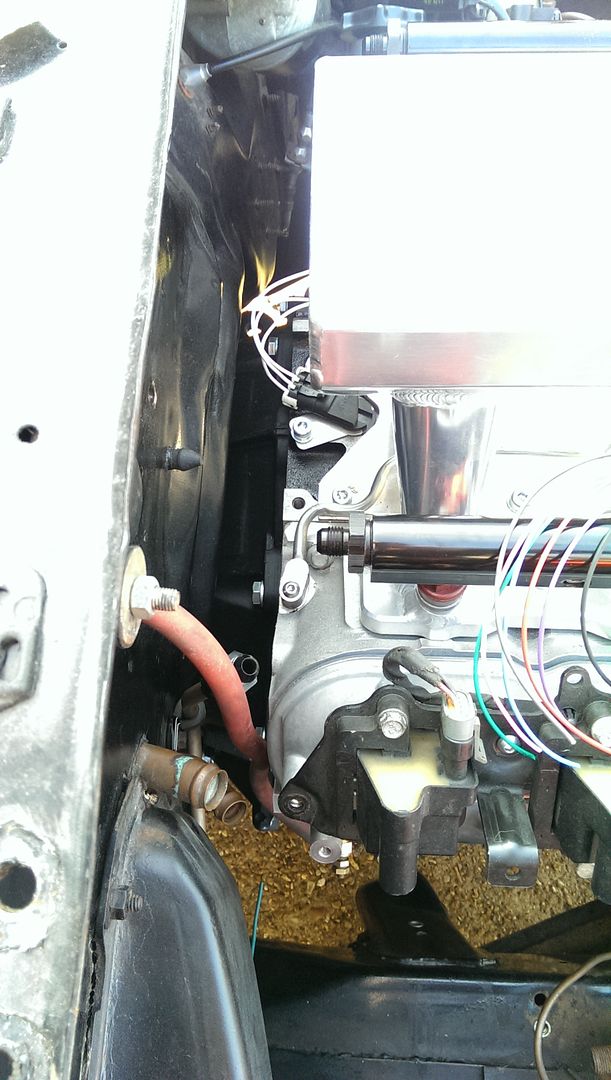

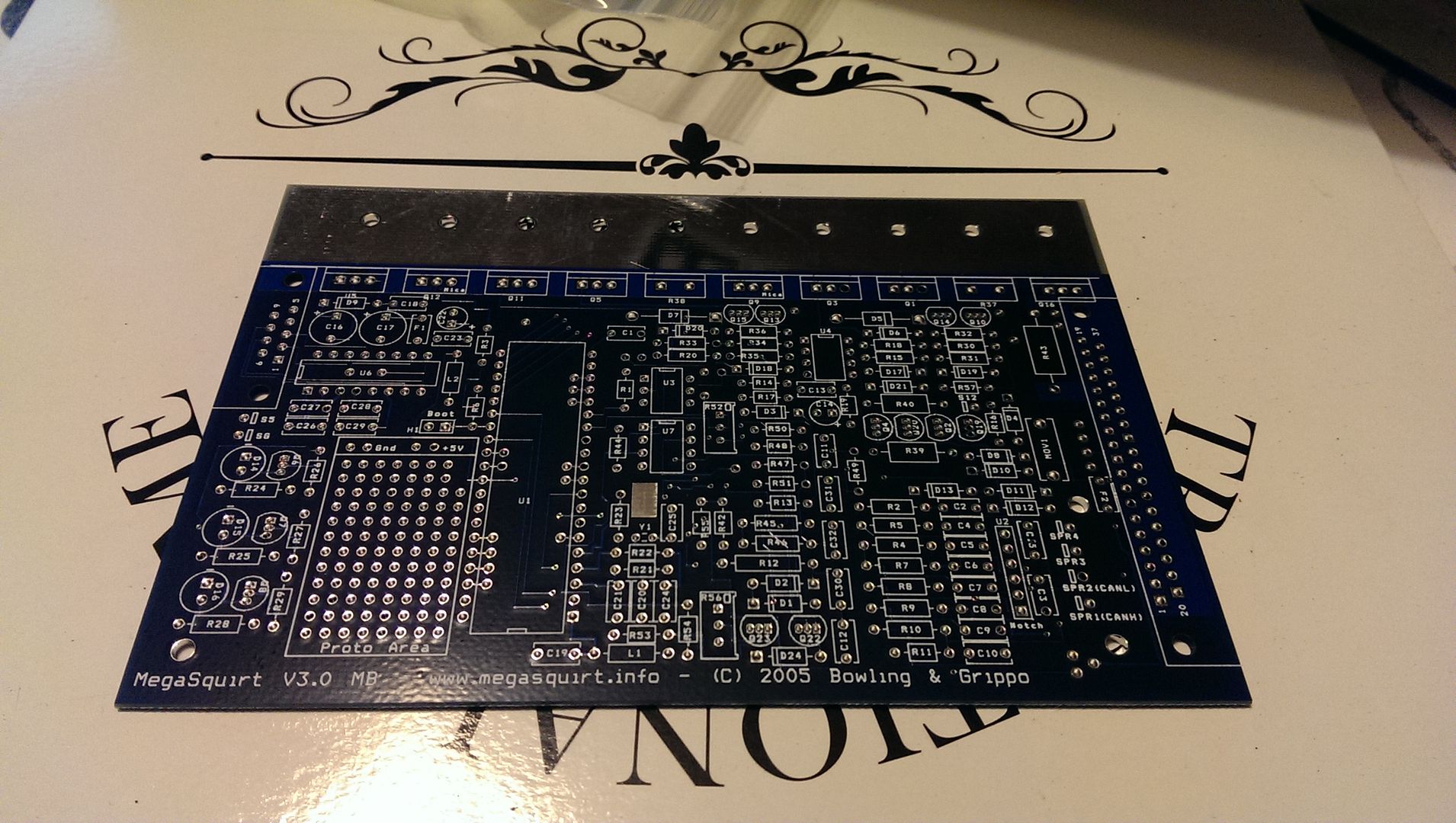

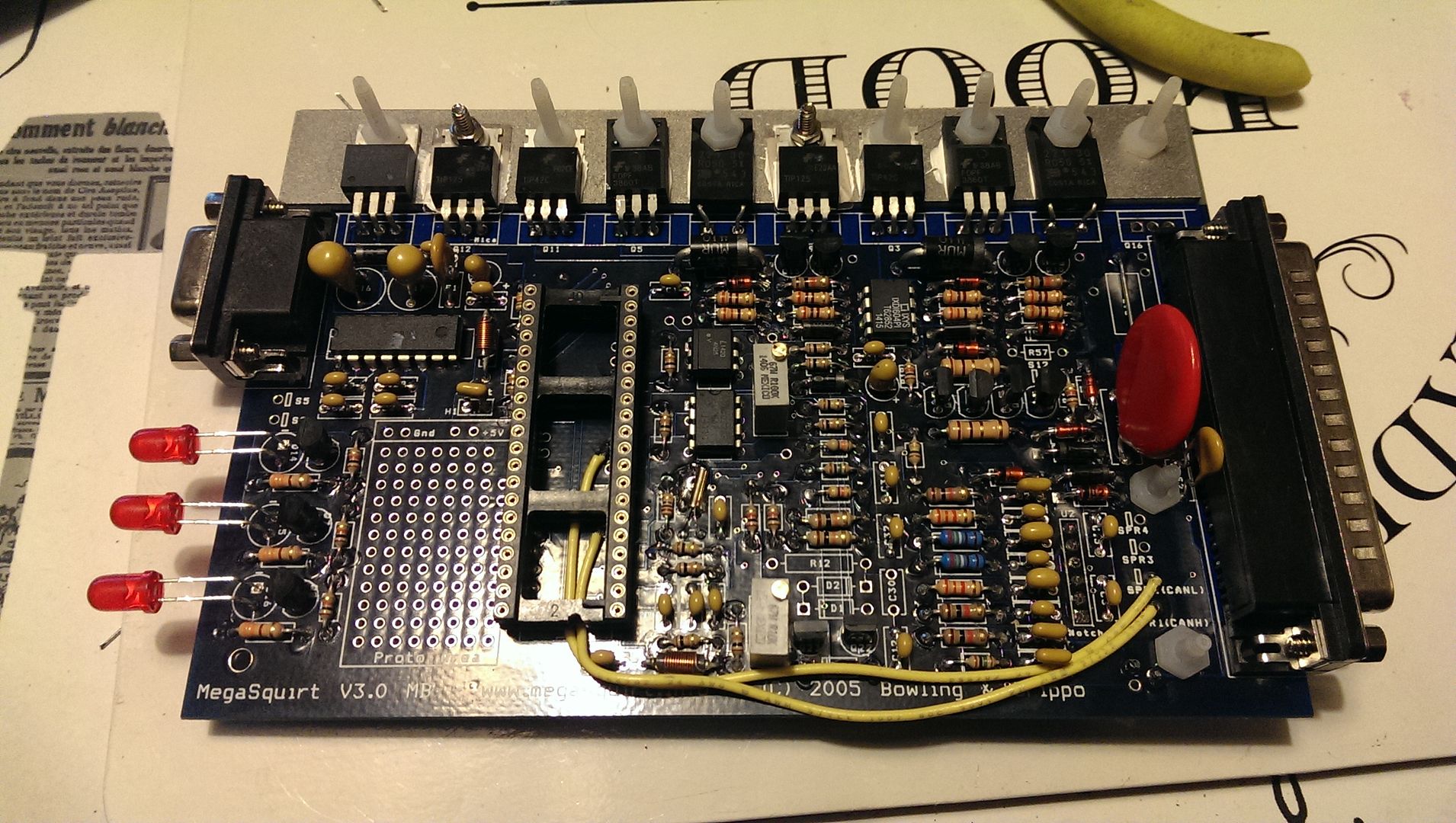

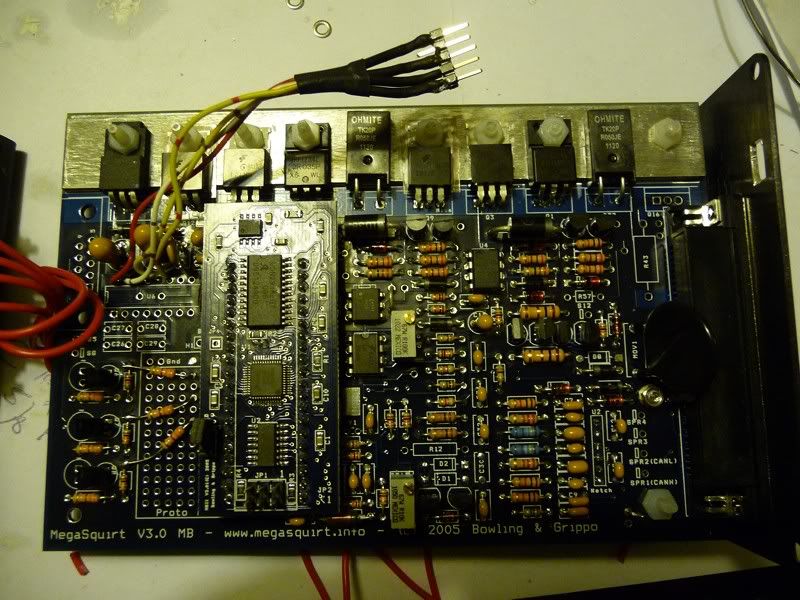

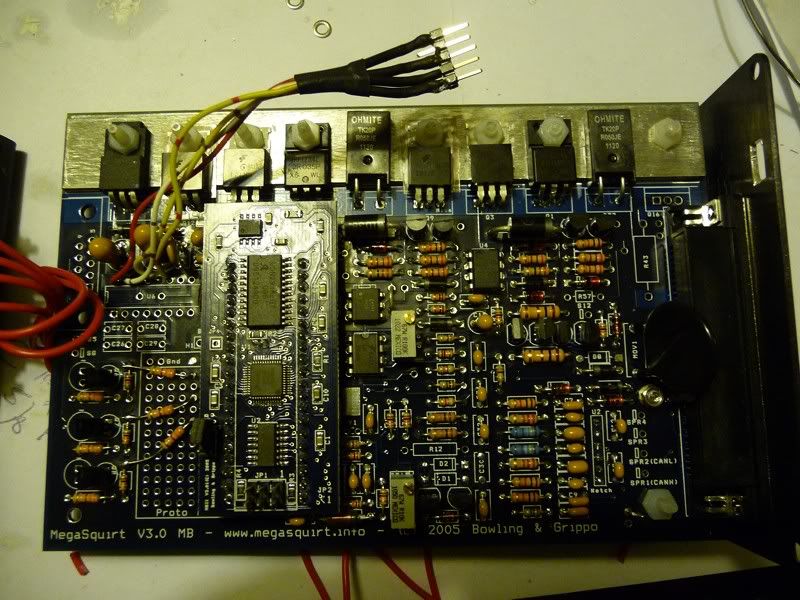

In the mean time I collected the parts to build myself a pretty hot 350 SBC, bored it out .060 and fitted forged pistons and rods, good heads which I ported myself and a moderate cam. I dropped a Holley multi port injection manifold and throttle body on it and built an MS2 ecu for it

I also did a few handling and structural upgrades while I was there. Including making some sub frame connectors, solid body mounts and some g-braces for the subframe to firewall. I also replaced the standard spindles and discs with A-body ones, 1" bigger for a bit more stopping power. Poly bushes, large anti roll bars and lowering springs were also fitted.

After a lot of hours I finally has something ready to paint. And I chose hugger orange. Nothing like a subtle colour....!

I bought this car back in 2011, having always hankered after a 2nd gen F-body. The intention was to keep it on the road and do little bits and pieces to it over the course of a few years and slowly get it upgraded into an everyday car.

That idea didn't last very long...

As soon as I dug into the car I discovered a lot of rust - perhaps unsurprising after finding out the car has been in the UK since 1982, with no rust protection whatsoever.

So I took it off the road and started what turned into 2 years of repairs.

When I bought the car, some bright spark had decided it would be a good idea to paint it like bumblebee... with a roller. Possibly the worst paint job I've seen. But the car was cheap.

It had a completely gutless 305 SBC fitted, which smoked a bit from the right bank. Other than that it drive OK, so I ran around in it for a couple of months.

After digging around in it for a while I started to realise just how badly bodged it had been. It had 11 months MOT on it when I bought it... possibly given by someone with a labrador and white stick...

It turned out to be rotten, really rotten. But I'd paid so little for it, and I had the time on my hands and a welder... to just patch it up.

I ended up stripping the whole shell back to bare metal and cutting out every piece of rot I could find. The only panel that I didn't end up having to repair or replace was the roof.

After that the underside of the car was treated with Jotamastic, and the rest of the bodywork with 2k epoxy primer.

In the mean time I collected the parts to build myself a pretty hot 350 SBC, bored it out .060 and fitted forged pistons and rods, good heads which I ported myself and a moderate cam. I dropped a Holley multi port injection manifold and throttle body on it and built an MS2 ecu for it

I also did a few handling and structural upgrades while I was there. Including making some sub frame connectors, solid body mounts and some g-braces for the subframe to firewall. I also replaced the standard spindles and discs with A-body ones, 1" bigger for a bit more stopping power. Poly bushes, large anti roll bars and lowering springs were also fitted.

After a lot of hours I finally has something ready to paint. And I chose hugger orange. Nothing like a subtle colour....!

Be PROUD.

Be PROUD.