Let me try! Is the distance from the bottom of the pick up to oil pan correct? Is it possible the pickup is sucking air where it is pressed in or the tube has a fracture? And yes get some measuring tools! A set of micrometers that measure in ten thousandths and a dial bore gauge that does the same. You will be amazed at what a lot of shops will pass off as good machining. Nothing like double checking things yourself for peace of mind. Mitutoyo has some budget friendly stuff that is very accurate. Remember, precision tools aren't an expense, they are an investment! An investment that will pay for itself the first time you find someone elses screw up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wrecker 350 runs! (but no oil to rockers!!)

- Thread starter bobs409

- Start date

Sorry its so late Bob I needed a break from my projects and took the fam into the Selkirk mts for some Huckleberry scouting. Actually found a couple of gallons its a bit early but it was fun. Bob I would agree with Ishiftem on the tools, and the crap the shops turn out. Check it all. Bob also when I see numbers I consider at the wear limit,I am always suspicious. A while back I suggested you start at the rear cam bearing and go forward and down from there. measure it all...... Also shoot for the middle on clearances. Bob the numbers dont lie. I use the extreme #s on my engines and my real estate. Barry

I have 1/4 inch space at bottom of pickup. Not sure if it is sucking air or not. Could I use some sealer there? The tube looked ok, I even swapped it over to the new pump.

Let me try! Is the distance from the bottom of the pick up to oil pan correct? Is it possible the pickup is sucking air where it is pressed in or the tube has a fracture? And yes get some measuring tools! A set of micrometers that measure in ten thousandths and a dial bore gauge that does the same. You will be amazed at what a lot of shops will pass off as good machining. Nothing like double checking things yourself for peace of mind. Mitutoyo has some budget friendly stuff that is very accurate. Remember, precision tools aren't an expense, they are an investment! An investment that will pay for itself the first time you find someone elses screw up.

The books say 3/8 to 1/2 from the bottom of the pan.I have 1/4 inch space at bottom of pickup. Not sure if it is sucking air or not. Could I use some sealer there? The tube looked ok, I even swapped it over to the new pump.

Engine is out and just waiting for me to tear it apart. It's SO damn humid out, it can wait!!!!

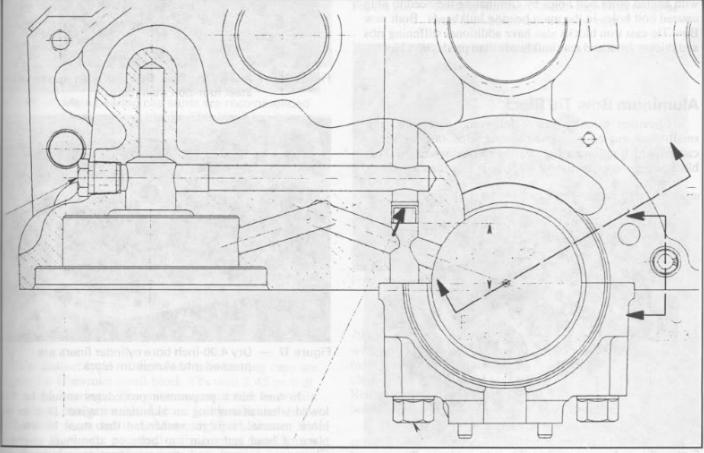

Thought I better ask about the correct procedure on measuring the cam bearing clearances.

I got a 1.4-6 inch Fowler dial bore gauge, 3 pc outside micrometer set and even a cam bearing install tool just in case it's needed. (will be used on my next engine anyway-regret not getting it sooner!)

What I thought I would do is to measure the cam journal with the outside mic and leave it set on that measurement. Put the dial bore gauge into that mic and "0" out the gauge. Then put the dial bore gauge into the cam bearing and record how far off the "0" is. That should be the clearance right?

Is that correct or is there a better way? They sure don't go out of their way with instructions on these tools. The bore gauge has one sheet that was all but useless. The outside mics had no instructions. I've never used these before so a general run down would have been nice especially with the bore gauge.

They sure don't go out of their way with instructions on these tools. The bore gauge has one sheet that was all but useless. The outside mics had no instructions. I've never used these before so a general run down would have been nice especially with the bore gauge.  Quite a bit of online searching has helped me alot but there's very little on doing the cam clearances for some reason. ??

Quite a bit of online searching has helped me alot but there's very little on doing the cam clearances for some reason. ??

Thought I better ask about the correct procedure on measuring the cam bearing clearances.

I got a 1.4-6 inch Fowler dial bore gauge, 3 pc outside micrometer set and even a cam bearing install tool just in case it's needed. (will be used on my next engine anyway-regret not getting it sooner!)

What I thought I would do is to measure the cam journal with the outside mic and leave it set on that measurement. Put the dial bore gauge into that mic and "0" out the gauge. Then put the dial bore gauge into the cam bearing and record how far off the "0" is. That should be the clearance right?

Is that correct or is there a better way?

They sure don't go out of their way with instructions on these tools. The bore gauge has one sheet that was all but useless. The outside mics had no instructions. I've never used these before so a general run down would have been nice especially with the bore gauge.

They sure don't go out of their way with instructions on these tools. The bore gauge has one sheet that was all but useless. The outside mics had no instructions. I've never used these before so a general run down would have been nice especially with the bore gauge.  Quite a bit of online searching has helped me alot but there's very little on doing the cam clearances for some reason. ??

Quite a bit of online searching has helped me alot but there's very little on doing the cam clearances for some reason. ??You are right. Mic the journal. Do it a few times so you get a good feel for it and your measurements are repeatable. Do not crank down on the mic. When you pull it of the journal there should only be a light drag. Hold it loosely in a vise and set up the bore gauge so it reads zero and leaves you with movement left +-. Make sure to move the bore gauge around in the mic so you are getting the smallest reading. Double check that your mic reading hasn't changed and you are good to go.

Ok, I think I found the problem. Too much clearance!

Here's all the juicy details:

#1 bearing has .0045 thousanths of clearance

#2 bearing has .0045 thousanths of clearance

#3 bearing, can't reach it

#4 bearing, can't reach it, engine stand mount prevents it

#5 bearing has .0035 thousanths of clearance

I checked, double checked and triple checked these readings and I keep coming up with the exact same thing so I feel confident these are accurate. (as accurate as the tool is anyway)

Cam is a Melling part # CCS2 (stock type) Journal sizes measure:

#1 1.869

#2 1.8685

#3 1.8685

#4 1.869

#5 1.869

Cam bearing holes are aligned the following way:

#1 2:30 & 6:00 o'clock positions (this one has 2 holes)

#2 6:00 o'clock

#3 6:00 o'clock

#4 6:00 o'clock

#5 9:00 o'clock

That last one being at 9:00 is an odd one isn't it? (all these are looking at the front of the engine)

I can see some wear marks on the front and rear bearings at the bottoms. A little scratching on the rear one. Journals on cam are perfect, no wear or scratches. I took some pics of the front and rear bearings but my camera is lousy at detail so not worth posting those.

So tally it up boys. What's the verdict?

Here's all the juicy details:

#1 bearing has .0045 thousanths of clearance

#2 bearing has .0045 thousanths of clearance

#3 bearing, can't reach it

#4 bearing, can't reach it, engine stand mount prevents it

#5 bearing has .0035 thousanths of clearance

I checked, double checked and triple checked these readings and I keep coming up with the exact same thing so I feel confident these are accurate. (as accurate as the tool is anyway)

Cam is a Melling part # CCS2 (stock type) Journal sizes measure:

#1 1.869

#2 1.8685

#3 1.8685

#4 1.869

#5 1.869

Cam bearing holes are aligned the following way:

#1 2:30 & 6:00 o'clock positions (this one has 2 holes)

#2 6:00 o'clock

#3 6:00 o'clock

#4 6:00 o'clock

#5 9:00 o'clock

That last one being at 9:00 is an odd one isn't it? (all these are looking at the front of the engine)

I can see some wear marks on the front and rear bearings at the bottoms. A little scratching on the rear one. Journals on cam are perfect, no wear or scratches. I took some pics of the front and rear bearings but my camera is lousy at detail so not worth posting those.

So tally it up boys. What's the verdict?

Sorry to hear all of this Bob. I've been a little tied up lately and had a problem with the computer so I've away from the site for a couple three weeks. It appears after reading thru this a couple of times you have been having way to much fun with this build. after all that said I see a couple of things that are of question to me. Are the last main clearance numbers based on mic readings with a mic of both the crank journals and bearings torqued in the block? I believe the witness marks on the front and mains are due to the crank being bowed but still in the serviceable use. I like a few others that have chimed in can not see why it got align honed, that just removes metal and added to your now to much main clearance. I have not found oversized cam bearings but again what is the clearance numbers by mic and snap gauge? I have had to mix and match a set and ream them to fit in a bad block but I do not think thats your problem. I will be around and will help as much as you need me. My cell is 860-941 4536.

Sorry to hear all of this Bob. I've been a little tied up lately and had a problem with the computer so I've away from the site for a couple three weeks. It appears after reading thru this a couple of times you have been having way to much fun with this build. after all that said I see a couple of things that are of question to me. Are the last main clearance numbers based on mic readings with a mic of both the crank journals and bearings torqued in the block? I believe the witness marks on the front and mains are due to the crank being bowed but still in the serviceable use. I like a few others that have chimed in can not see why it got align honed, that just removes metal and added to your now to much main clearance. I have not found oversized cam bearings but again what is the clearance numbers by mic and snap gauge? I have had to mix and match a set and ream them to fit in a bad block but I do not think thats your problem. I will be around and will help as much as you need me. My cell is 860-941 4536.Derry, yep way too much fun. I just love tearing this engine apart so much, I'm now on the third time.

Ok, your talking crank bearings first. I checked those with plastigage. I just unbolted a cap, cleaned the area free of oil where I put the plastigage and torqued the cap back down. (all other still installed) Then removed and read it. I only did #1 & #5 on this last check but did all mains and rods when I assembled it the first time. All readings were posted earlier.

I don't have a snap gauge. (uh oh, do I have to buy another tool??) What I did was to mic the camshaft journals and lock the mic on that setting. I gently secured it in my bench vise and then set the dial bore gauge to "0" while it was in that mic. Then took the bore gauge to the cam bearings still in block and read how far off the "0" it was. (readings above)

I'm quite baffled as to how you correct loose clearances for a camshaft? I thought different size bearings would be available much like for mains and rods.

All I find are oversize bearings like .10 & .20 but that's the outside diameter. I need a smaller inside diameter bearing. Or an oversized cam! How do I tighten up the clearances?

How do I tighten up the clearances?

Ok, your talking crank bearings first. I checked those with plastigage. I just unbolted a cap, cleaned the area free of oil where I put the plastigage and torqued the cap back down. (all other still installed) Then removed and read it. I only did #1 & #5 on this last check but did all mains and rods when I assembled it the first time. All readings were posted earlier.

I don't have a snap gauge. (uh oh, do I have to buy another tool??) What I did was to mic the camshaft journals and lock the mic on that setting. I gently secured it in my bench vise and then set the dial bore gauge to "0" while it was in that mic. Then took the bore gauge to the cam bearings still in block and read how far off the "0" it was. (readings above)

I'm quite baffled as to how you correct loose clearances for a camshaft? I thought different size bearings would be available much like for mains and rods.

All I find are oversize bearings like .10 & .20 but that's the outside diameter. I need a smaller inside diameter bearing. Or an oversized cam!

How do I tighten up the clearances?

How do I tighten up the clearances? Bob I missed how you measured but you got the info you needed. Cam bearings are cheap enough to just put another set in and re-check. They could have gotten a bad set. I don't use clevite any more (made in Mexico) had a set of Mains dissolve the babbit while breaking in. Durabond cam bearings have always been good for me. Remember that the clearance on a cam bearing is partly made from the interference fit in the block. so the over size on the outer you have found is from spinning a bearing in the block. when that happens the Machinist cuts the cam holes for the over size and right amount of interference on the new bearings.

Bob I missed how you measured but you got the info you needed. Cam bearings are cheap enough to just put another set in and re-check. They could have gotten a bad set. I don't use clevite any more (made in Mexico) had a set of Mains dissolve the babbit while breaking in. Durabond cam bearings have always been good for me. Remember that the clearance on a cam bearing is partly made from the interference fit in the block. so the over size on the outer you have found is from spinning a bearing in the block. when that happens the Machinist cuts the cam holes for the over size and right amount of interference on the new bearings.

Looking at new tools; outside micrometers, inside bore gauge as well as cam bearing tool.

Looking at new tools; outside micrometers, inside bore gauge as well as cam bearing tool.