You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting new engine this week lifter question

- Thread starter Iowa409

- Start date

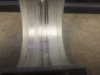

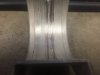

Wow. A lot of schmegma in and on that flange.

Some of that is the grease that came with the ARP flywheel bolts for mounting, some of the rest of it was just debris it picked up on the floor and kitty litter after removed, but as agreed there was to much crap left in the motor. It just set to long open and that builders grease is sticky stuff, it all got started(tried) that way, that wont happen again.

A picture of rear main.

Attachments

-

DF6E2E2B-F82B-4E38-9F4A-897592EFFD85.jpeg57.9 KB · Views: 43

DF6E2E2B-F82B-4E38-9F4A-897592EFFD85.jpeg57.9 KB · Views: 43 -

8F990F81-DF29-4C18-8E0F-B24C2C2BC504.jpeg32.7 KB · Views: 42

8F990F81-DF29-4C18-8E0F-B24C2C2BC504.jpeg32.7 KB · Views: 42 -

298BC328-D94F-4E11-8FF8-64D4705F4097.jpeg51.7 KB · Views: 40

298BC328-D94F-4E11-8FF8-64D4705F4097.jpeg51.7 KB · Views: 40 -

30672D41-D3A2-4534-B429-2BB772072F56.jpeg50.3 KB · Views: 40

30672D41-D3A2-4534-B429-2BB772072F56.jpeg50.3 KB · Views: 40 -

111ACF2D-F1B4-459D-8D93-3E81D6A72396.jpeg48.3 KB · Views: 38

111ACF2D-F1B4-459D-8D93-3E81D6A72396.jpeg48.3 KB · Views: 38 -

A3342D27-CF10-4160-9924-6EB1A65684B2.jpeg68.5 KB · Views: 38

A3342D27-CF10-4160-9924-6EB1A65684B2.jpeg68.5 KB · Views: 38 -

D786FC7E-28BE-4124-90D7-34C52B70079B.jpeg74.7 KB · Views: 39

D786FC7E-28BE-4124-90D7-34C52B70079B.jpeg74.7 KB · Views: 39

Was the half of the bearing with the oil groove in it in the block or in the cap?

Well it say's UPPER right on it, so if I remember correctly it was in the upper half of the cap, I am sure of it.Was the half of the bearing with the oil groove in it in the block or in the cap?

Just got me thinking, you said the filter had no oil in it.

What do you have for a oil filter?

What do you have for a oil filter?

I bought a oil filter adapter from Show Cars, that lets you convert to a spin on filter PH2, I suppose there is a chance I did not intall it correctly, there were no directions to speak of, so???? if I was spinning the oil pump shaft with the drill, that filter should have filled up, correct? But yet is showed 80 psi on the mechanical gauge coming straight off the port above the oil filter where the oil pressure sensor/switch goes. I do not fully understand the oiling galleys/routes, so maybe I was bypassing the filter or something? I need to be sure when It goes back together to find a way to verify, its filling. Maybe leave it loose and watch for oil to spill over the side?

For what it's worth,the torque on those main cap bolts is 100 ft.lbs.,so they may not have been as tight as you thought.It looks like some debris was pinched between the crank journal and the bearing.I don't know if even .030 will clean that up.

Going to be hard to say until he gets it on his bench, yes its deep.

I talked to Clevite today they no longer produce anything other than a .10 for the rear, but said I should be able to find some old stock sitting out there, .20, .30.40 should be floating around, its spooky how rare some of this stuff is becoming.

By looking at that bearing, something real hard looks like it got between the crank and bearing, on that I agree Don, sharp eye there buddy, what I don't quite get is how it could get between the two surfaces with that tight of tolerances. I want to explore the no oil in the filter a little more, I am going to see if I can get a better handle on the oil passages and oil routing and my install of that adapter.

I an hoping to drop it off in the morning, he will not get to it for a few days, but he will look at it when it comes in and give me an idea how rough its going to be.

I talked to Clevite today they no longer produce anything other than a .10 for the rear, but said I should be able to find some old stock sitting out there, .20, .30.40 should be floating around, its spooky how rare some of this stuff is becoming.

By looking at that bearing, something real hard looks like it got between the crank and bearing, on that I agree Don, sharp eye there buddy, what I don't quite get is how it could get between the two surfaces with that tight of tolerances. I want to explore the no oil in the filter a little more, I am going to see if I can get a better handle on the oil passages and oil routing and my install of that adapter.

I an hoping to drop it off in the morning, he will not get to it for a few days, but he will look at it when it comes in and give me an idea how rough its going to be.

Last edited:

Fill the filter before pre-oiling.

Foreign material in the engine for sure...look at how the thrust face of the rear main is scored. Plus, the bearing material that is fretted to the sides of the scratch is material that's been displaced from the scratch itself.

Likely the crank is not hurt too bad. Those bearings are soft enough to let stuff imbed w/o scoring the crank, in most cases.

Foreign material in the engine for sure...look at how the thrust face of the rear main is scored. Plus, the bearing material that is fretted to the sides of the scratch is material that's been displaced from the scratch itself.

Likely the crank is not hurt too bad. Those bearings are soft enough to let stuff imbed w/o scoring the crank, in most cases.

Last edited:

Fill the filter before pre-oiling.

I did not do that, I assumed the priming tool would have got the oil there, but I certainly will on rebuild, thank you.

I did not do that, I assumed the priming tool would have got the oil there, but I certainly will on rebuild, thank you.

It should have filled, if you had oil pressure, unless your bypass never let it get to the filter.

Please take the rear cam plug out of the block and check the rear cam bearing and take many pictures for record and future help.

Ok will do, Phil and several people have mentioned that cam bearing as a concern, while its down this far it sure don't hurt to check it, I only want to build this once, WITH success!!!It should have filled, if you had oil pressure, unless your bypass never let it get to the filter.

Please take the rear cam plug out of the block and check the rear cam bearing and take many pictures for record and future help.