Thanks Gav,

Looks like I should make one of those.

Cheers

Looks like I should make one of those.

Cheers

Don't do that Grub.Thanks Gav,

Looks like I should make one of those.

Cheers

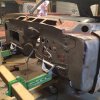

we got stuck in to replacing the rear floor pans and now working on the front.

we got stuck in to replacing the rear floor pans and now working on the front.

Yeah, easily manageable with two of us.Looks like a great "blank canvas" to start on. Were you as surprised as I at how light the bare frames are?

Coming along very niceChassis is now painted and and bought it home today.

Gav

Thanks Brian,it is a way but there was no rubber bushing under the factory shocks, Looking good thou

Yup, and the knee's aren't like they used to be.Great job, Gav.Lot's, of kneeling down work, huh?

HA HA, yeah. It was one of those ones we i kept on saying to myself "put the fuel line in" Put the fuel line in" and then TOO LATE and it was a Homer Simpson moment "DOH"Hey Gav, I see the fuel line clip there but no fuel line...? That front section of fuel line is easy to install when the upper control arm isn't bolted in place yet.

.

.